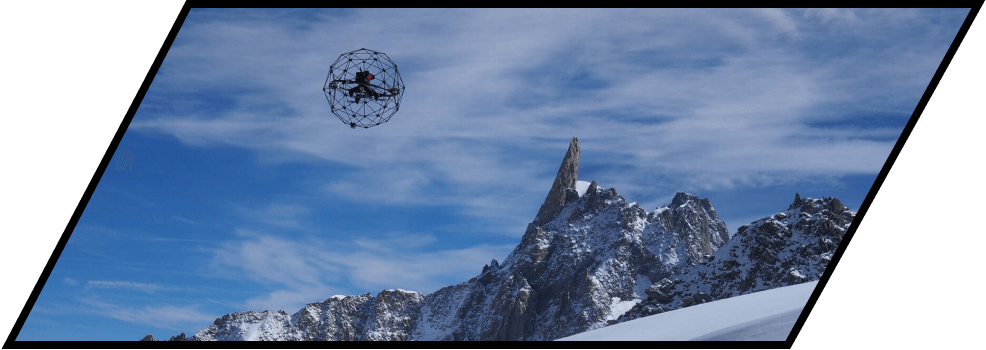

By enabling remote visual inspection in any indoor environments, Elios prevents the need for workers to enter hazardous places or face dangerous situations.

Elios is deployed and ready to gather visuals within a minute. Performing an entire inspection is no longer a matter of days but hours.

Scaffolding, rope access, or crane are no longer needed to perform visual inspections. Elios gathers visuals of the most complex and cluttered spaces for you.

The sophisticated onboard technology enables us to gather data and locate issues remotely. Be it taking photos to ensure welds or bolts are up to spec, through to thermal imaging of a moisture leak in tunnels.. we can achieve this information and more, from a safe distance.

Elios is capable of delivering images up to 0.2 mm/px, and HD video feedback, even in complete darkness.

Although possibilities are vast for the Elios Drone, below are a series

of examples of which we’ve utilised the technology

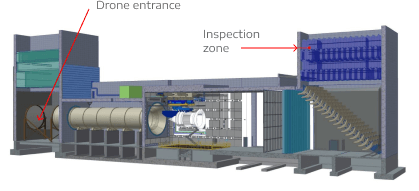

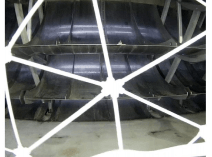

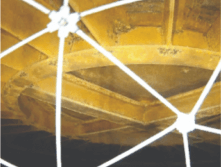

Jet Engine Test Facility Inspection: The jet engine test beds used in the aeronautical industry for Quality Control and R&D require strict maintenance. Traditional methods of inspection involve lengthy and inefficient operations

READ MOREThe jet engine test beds used in the aeronautical industry for Quality Control and R&D require strict maintenance. Traditional methods of inspection involve lengthy and inefficient operations, which in turn result in high costs and downtime. Elios offers a cheaper, quicker and safer way of inspection by capturing quality data of all the key elements within minutes.

Ten flights of 10 minutes each were carried out for the inspection in various parts of the facility. Most of the flights were performed beyond line of sight (BLOS) with the camera looking at 90° up. The inspection could easily be carried by Elios with its ability to navigate around unknown, complex and very reduced spaces.

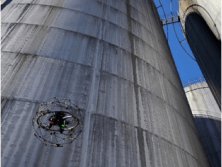

Above - Ground Hydrocarbons and Chemicals Storage Tanks: Between five and ten flights with Elios, each flight taking about ten minutes, were necessary to complete the inspection of a single tank.

READ MOREEvery 3 - 15 years, depending on the substance they have contained, TAU AG performs a thorough inspection of each storage tank.

At 25 meters above ground, in pitch-dark conditions, these inspections require working at height and implies having humans entering the inner confined space of tanks. Usual methods such as scaffolding or rope access are costly and time-consuming. With these aspects in mind, TAU AG requested the intervention of Elios for the inspection of the 25m tall, 18m diameter fixed-roof storage tanks.

Accessing the Unaccessible UNDERGROUND: Elios drone has performed multiple missions in the North American Palladium (NAP) Lac des Iles mine near Thunder Bay, Ontario.

READ MORENo GPS, No LIGHT, and No HUMANS - send in Elios.

The Elios drone has performed multiple missions in the North American Palladium (NAP) Lac des Iles mine near Thunder Bay, Ontario.

Underground mines can be dangerous places, especially after excavation. One need for more information, is in the open cavern resulting from the mining and excavation, called an open stope. The areas, which can be unstable, are completely inaccessible by law to employees because of their extreme danger.

Before the introduction of the Elios drone, the only tools available to assess conditions before backfilling was a Cavity Monitoring Survey (CMS) on a cart or boom arm: ineffective at getting through the tall piles of muck on the floor, or in going around corner, or seeing beyond a deep brow.

standing safely under supported ground, well away from the restricted area, the team flew the Elios against the back of the stope despite the presence of explosives, and were able to accurately evaluate the height and condition. Using this data, the company can use AutoCad to create a rough model of the stope, used to evaluate risks and plan work.

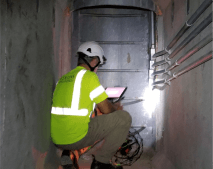

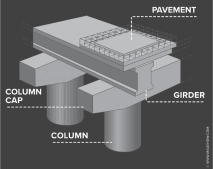

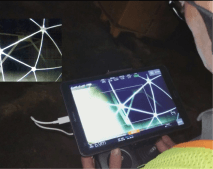

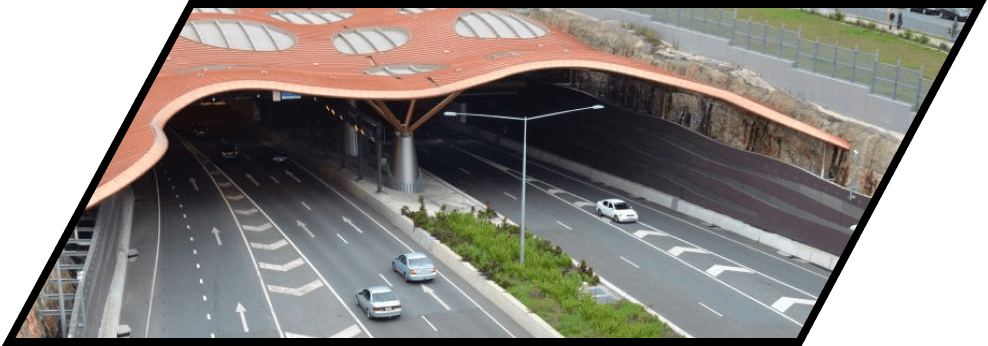

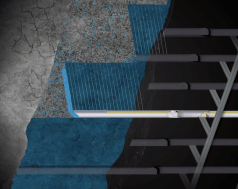

Bridge Inspection: Elios is used for bridge inspections in Minnesota, USA, navigating the difficult to reach spaces under bridges between beams and inside of box girders.

READ MOREElios is used for two different types of missions: flying under smaller bridges to check for potential issues, including accessing the difficult spaces between beams; and flying in the confined spaces of box girders on larger bridges. Both missions save the company significant time, money and resources while contributing to the safety of the engineers.

Engineers inspect the bridges to detect issues like cracking in concrete, problems with bearings, or movement of the bridge. Corrosion, paint loss, and rust are other indications that the bridge may require further examination. Without a drone, inspecting the underside of structures or confined spaces can be prohibitively expensive.

The drone requires no traffic control to transport, no additional time to reach the site, and can be operated by a single inspector compared to the 2 or more personnel required to operate the truck. Elios gives us a much higher quality inspection. If we can find things earlier, we can save our clients money and take care of problems before they become larger.